-

Emergency & Unplanned Onsite Machining Services

When equipment failure cannot wait, precision onsite machining keeps operations moving.

On-Site Machining

Bringing the workshop to clients for all on-site machining requirements

Emergency Industrial Maintenance

Onsite machining expertise when unplanned downtime threatens operations.

Unplanned equipment failures do not wait for maintenance windows. When assets fail, distort, or begin leaking without warning, immediate intervention is required to prevent extended downtime, safety risks, and production losses. BLJ In-Situ Solutions provides emergency and unplanned onsite machining services to restore critical components quickly and safely, directly at site.

This service is designed for situations where traditional workshop repair is impractical or impossible due to asset size, location, or time constraints. By machining in place, BLJ helps clients stabilise operations, protect shutdown schedules, and avoid unnecessary replacement costs.

When Emergency Onsite Machining Is Required

Emergency onsite machining is typically required when:

- Flange faces distort, corrode, or are damaged unexpectedly

- Gaskets fail during commissioning or post-startup

- Vessels or exchangers cannot be dismantled within outage windows

- Shafts or keyways fail in service

- Transport or handling damage is discovered late in the project lifecycle

- Unplanned shutdowns threaten extended downtime

In these situations, removing components for workshop repair is often not viable. Onsite machining allows corrective work to be completed immediately, using controlled and proven machining methods.

Supporting Unplanned Shutdowns and Outage Recovery

Emergency machining frequently occurs alongside unplanned or partially planned shutdowns. BLJ works closely with client maintenance teams to integrate machining activities into active outage environments, ensuring work is completed safely and efficiently under time pressure.

Our technicians are experienced in:

- Working within live or isolated plant environments

- Coordinating with shutdown supervisors and mechanical teams

- Executing machining scopes within tight access and time constraints

- Supporting restart and recommissioning activities

This integrated approach ensures that machining works do not become the critical path delay in outage recovery.

Onsite Machining Capabilities for Emergency Response

BLJ’s emergency onsite machining services cover a wide range of industrial assets, including:

- Flange facing and sealing surface restoration

- Vessel and heat exchanger channel machining

- Shaft and journal machining

- Keyway cutting and repair

- Pipework flange correction

- Temporary machining solutions to maintain asset operation

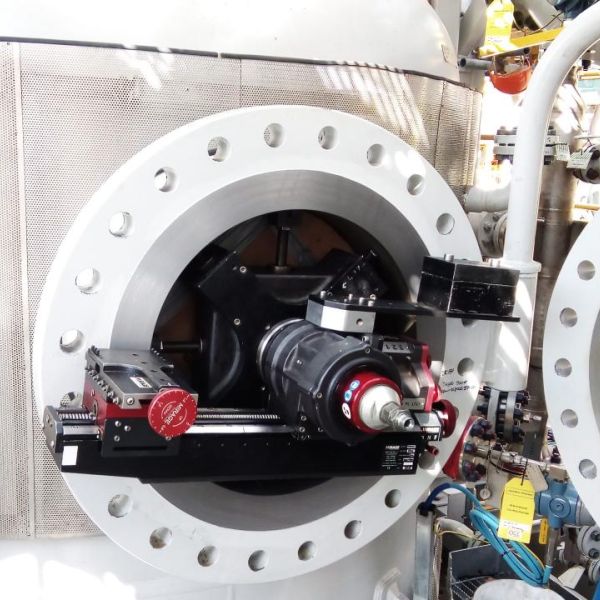

All work is performed using specialised in-situ machining equipment designed for accuracy, repeatability, and controlled material removal in field conditions.

Reducing Rework and Post-Startup Issues

One of the most common causes of post-startup failure is incomplete or inaccurate repair during unplanned maintenance. Emergency machining carried out without precision often leads to repeat leaks, bolting failures, or premature gasket breakdown.

BLJ’s controlled onsite machining processes reduce rework by:

- Restoring components to specification rather than applying temporary fixes

- Ensuring flatness, surface finish, and alignment are achieved

- Supporting correct gasket seating and controlled bolting outcomes

- Reducing the likelihood of secondary failures after restart

- This approach protects long-term asset reliability, not just short-term restart targets.

Why BLJ for Emergency Onsite Machining

BLJ is not a general machining contractor. Emergency onsite machining requires technical judgement, disciplined execution, and the ability to work under pressure without compromising quality or safety.

Clients engage BLJ because we offer:

-

Proven emergency response capability

-

Integrated machining and mechanical maintenance expertise

-

Equipment suited to complex, high-risk environments

-

Experience working within shutdown and outage frameworks

-

Practical solutions that prioritise operational recovery

Enquire Today for our Emergency Onsite Machining Services

Fill out the form below or call us now to arrange your emergency onsite machining services with BLJ In-situ solutions.

Emergency & Unplanned On-site Machining Services FAQ’s

Emergency and unplanned onsite machining services involve precision machining carried out directly at an industrial site following unexpected equipment failure. This approach eliminates the need to remove large or fixed components for workshop repair, allowing critical assets to be restored quickly as part of industrial maintenance or unplanned shutdown activities.

Our on-site machining solutions are ideal for any plant or construction project which needs quick and efficient in-situ machining services. Field maintenance is the best choice for planned or emergency shut-downs to mill, bore, drill, trepan or any maintenance task where adjustments to machinery are required.

Where traditionally equipment would need to be disassembled and machined off-site in a workshop, our portable machining equipment allows our expert team to conduct work in-situ.

Onsite machining is the preferred solution when equipment cannot be removed due to size, access limitations, or time constraints. It is commonly used during unplanned shutdowns to repair damaged flange faces, vessel sealing surfaces, shafts, or pipework without extending downtime or delaying plant restart.

By performing machining in place, emergency onsite machining removes transport delays, disassembly requirements, and workshop scheduling constraints. This allows mechanical maintenance teams to complete repairs faster, supporting shutdown recovery and reducing the risk of extended or secondary outages.

Emergency machining is not a temporary fix when completed correctly. Precision onsite machining restores flatness, alignment, and surface finish, supporting correct gasket seating and controlled bolting. This reduces the likelihood of repeat leaks, rework, or post-startup failures.

Yes. Onsite machining is frequently delivered alongside shutdown services, either during planned outages or in response to unplanned failures. Coordinating machining with mechanical maintenance and shutdown teams helps ensure repairs are completed efficiently within outage timeframes.

Mobilisation time depends on location, scope, and site access requirements. BLJ is structured to respond rapidly to emergency and unplanned machining needs, supporting industrial facilities across multiple sectors when urgent intervention is required.

We look forward to working with you.

For more information on our services, please fill out the form and one of our team members will be in touch.

admin@bljiss.com.au

admin@bljiss.com.au 07 3245 2203

07 3245 2203